Rubber Gasket

A gasket is seal which is mechanically designed to fill up spaces between two or more matting surfaces to prevent leakage of the content into the adjoining object when placed under compression. These gaskets come in various designs and specifications classified on the basis of the budget, material and physical parameters. However, the most common type used in the industries which suits everyone's budget and requirements are rubber gaskets. These rubber gaskets are punched out in the shape from sheets of various synthetic and natural rubbers.

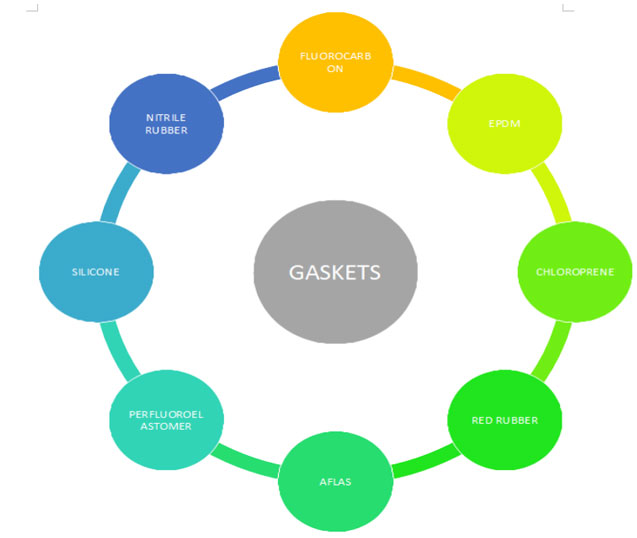

The gaskets designed and manufactured from the rubber sheets are extremely cheap which can be used in the industry within the given pressure and condition units. There are primarily eight types of rubbers which are used for the process of manufacturing gaskets.

DESCRIPTION OF THE VARIOUS RUBBER SHEETS USED FOR GASKET MAKING�.

Although there are a variety of rubber sheets that can be used for the application but the most common forms used are:

NITRILE OR BUTA-N RUBBER

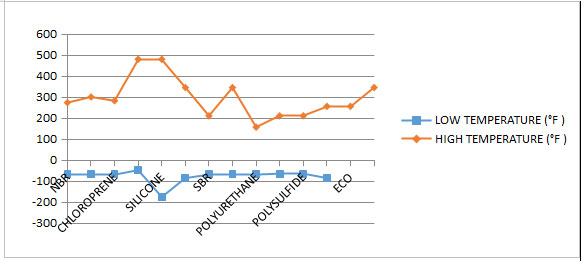

These are the most common form of elastomer which is used for the production of the rubber gaskets because of their outstanding properties. It is most commonly used in the gasket ting of petroleum products because of the excellent resistance. The other properties of the BUNA-S which give it an excellent working range is because of its compression set, tear and abrasion resistance. However, it does not offer a good range of resistance against ozone, sunlight and weather. Hence, it is avoided in applications where the gasket is exposed to the direct sunlight or electrical equipment since they generate ozone.

FLUOROCARBON RUBBER

Fluorocarbons, such as Viton or FKM, are another popular gasket material because of their extreme compatibility with high temperature, heat, oil and chemicals. The Fluorocarbons are also known to show extreme resistance against the following:

• Aromatic aliphatic compounds

• Halogenated hydrocarbons

• Concentrated acids

• Alkalis

• Animal and vegetable oils

However, the brown and green colored grades of fluorocarbons are avoided because the clay fillers used in them are subjected to chemical attack and wear and tear that follows.

EPDM

This black plate finish elastomer has extremely extraordinary resistance to weathering, ozone and UV. Also, the EPDM gaskets are resistant against chemical exposure/decay, animal and vegetable oils, steam, water and oxygenated solvents along with showing excellent electrical properties.

CHLOROPRENE

However, it is not the top choice of rubber sheet for gasket making but it is widely used in the industry because of its properties of:

• Moderate resistance to petroleum products

• Resistance towards ozone and weather

• Great compression set

SILICONE RUBBER

Silicone gaskets are an extremely versatile gasket making component with a wide range of applications. These applications are due its excellent properties such as temperature, weather and fire resistance with an excellent compression set.

RED RUBBER

Red or SBR rubber sheets are recommended for low grade applications such as gaskets in plumbing or heating operations. They are the lowest cost gaskets with good ageing and abrasion resistance.

AFLAS

These are mostly preferred by in gaskets which come in contact with ammonia, amine, oil or sour gas because of their resistance and stable chemical nature.

PERFLUOROELASTOMER

These are used for some chemical gasket applications which require extensive exposure to high temperature, pressure and chemicals.

The gaskets we offer are manufactured using qualitative raw material and widely accepted in diverse industries for their qualitative features. These gaskets are thoroughly tested for quality before they are dispatched to the clients base. We offer the entire assortment in various specifications that can also be customized as per clients requirements.

The gaskets we offer are manufactured using qualitative raw material and widely accepted in diverse industries for their qualitative features. These gaskets are thoroughly tested for quality before they are dispatched to the clients base. We offer the entire assortment in various specifications that can also be customized as per clients requirements.Silicon Sponge Gaskets

Gaskets are very widely used application of rubbers in all areas of domestic and industrial setting. However, choosing the hard or soft gaskets are not the right options always. In fact in certain applications only sponge gaskets can be used which are widely famous as well. They are popularly of two categories:

• CLOSED CELL SPONGE GASKET

These gaskets are mostly used in high pressure situations.

• OPEN CELL SPONGE GASKET

These gaskets are used when a spring is desired to push back the materials in place after usage and wont collapse due to excessive repeated pressure.

• TYPES OF GASKET (BASED ON MATERIAL)

The above two categories are unique and can be made using the following rubber types:

• NEOPRENE BLEND

The neuroprene blend rubber gaskets are used in low pressure situations where there are only a limited number of sealing – resealing is required.

• EPDM BLEND

The EPDM blend rubber gaskets are the most economical form of sponge gaskets that can take a great level of compression. These are mostly used to absorb shocks or to deaden sound waves.

• SILICONE

The sponge gaskets manufactured from the silicone rubber are often used to endure medium pressure applications in which high temperatures are involved.

• NITRILE POLYETHELYNE

The nitrile polyethelyne rubber sponge gaskets are the most economical option of sponge gaskets but can be only used under low pressure and temperature settings or conditions. Hence, if used they have to be replaced very frequently due to their extreme wear and tear.

USES OF SPONGE GASKETS

The sponge gaskets are very widely used in our day to day regular lives. However, some of the examples of their usage are:

• Seals for variety of things and materials

• Cabinet bumpers

• Adhesive backed tapes

• Spacers

• Cushioning

• Shock absorber

• Deaden sound waves

We are reckoned as one of the prominent manufacturers of rubber gaskets that are widely used for sealing applications. We execute several production methods to produce the right gasket for the application. Our range is fabricated using solid and sponge materials and a variety of compounds that includes Neoprene, EPDM, Nitrile, Butyl, Viton and Silicone. The entire range is manufactured that conforms to ISO standards. Available in various colors, these can also be customized as per clients’ specifications.